Product Range

Product Range

GSC Schwörer develops, designs and manufactures innovative solutions in the field of mechanical and electromechanical drive technology. Our customers can choose from a wide range of products – from customised gears and gear parts to complete geared motors.

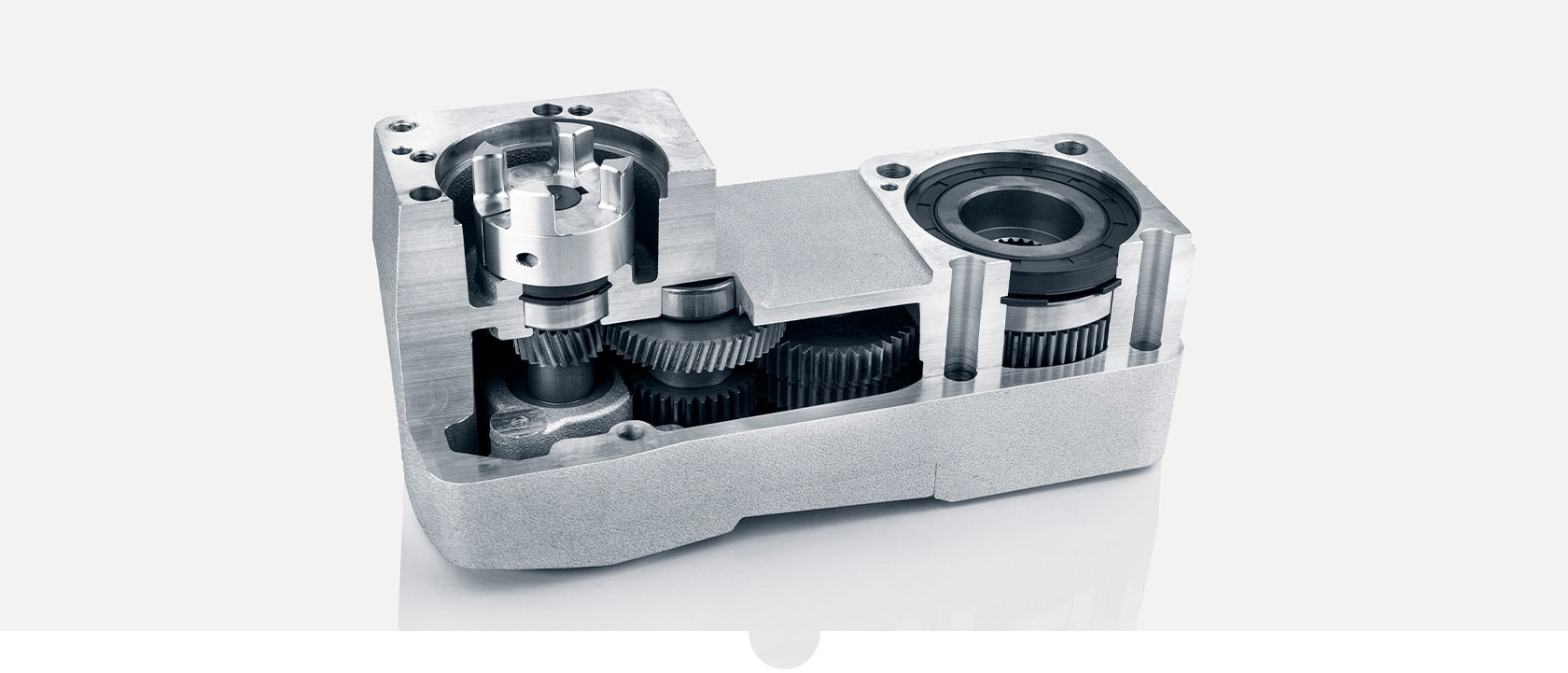

Gears & Geared Motors

-

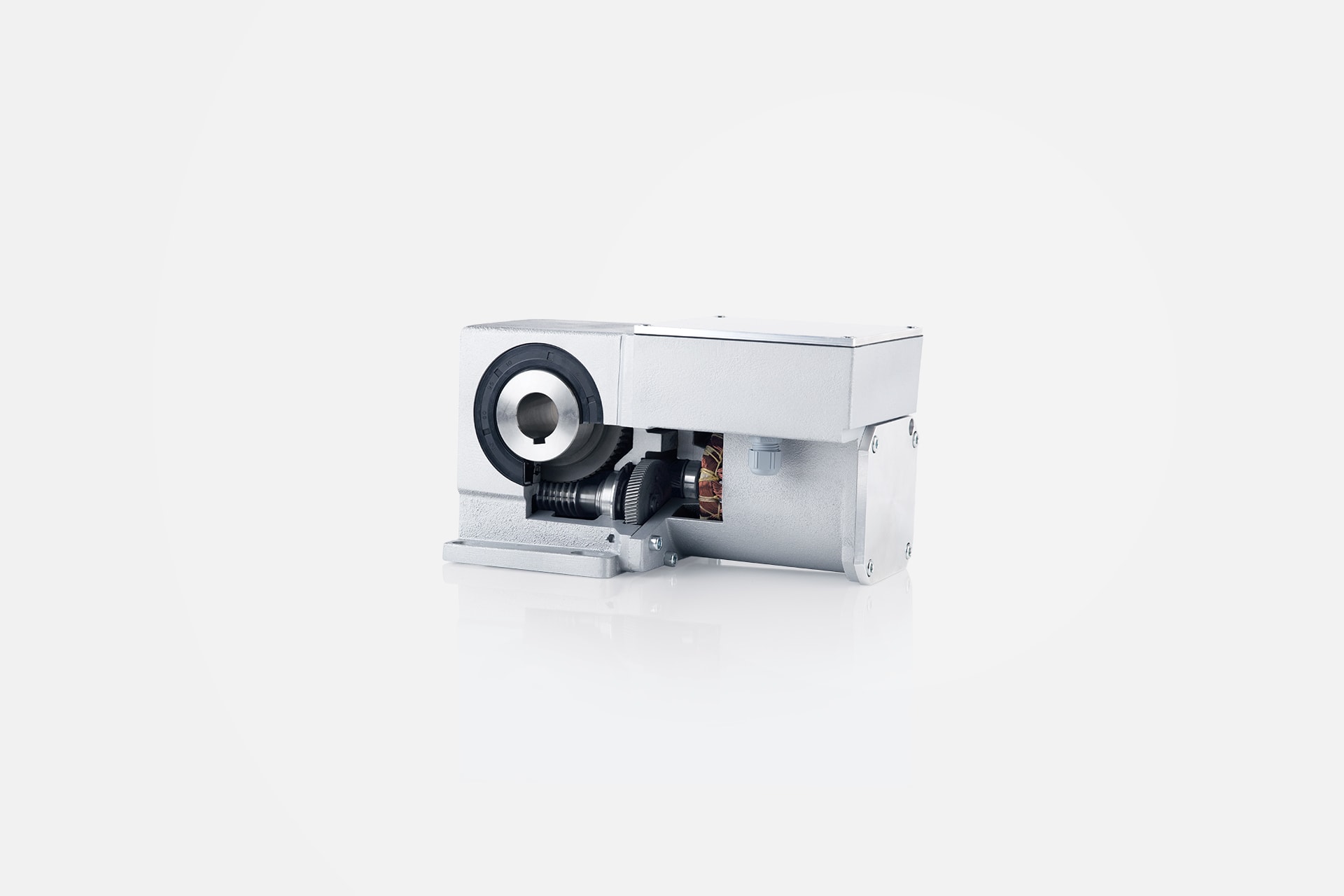

Geared motorsGeared motors

Geared motorsGeared motors -

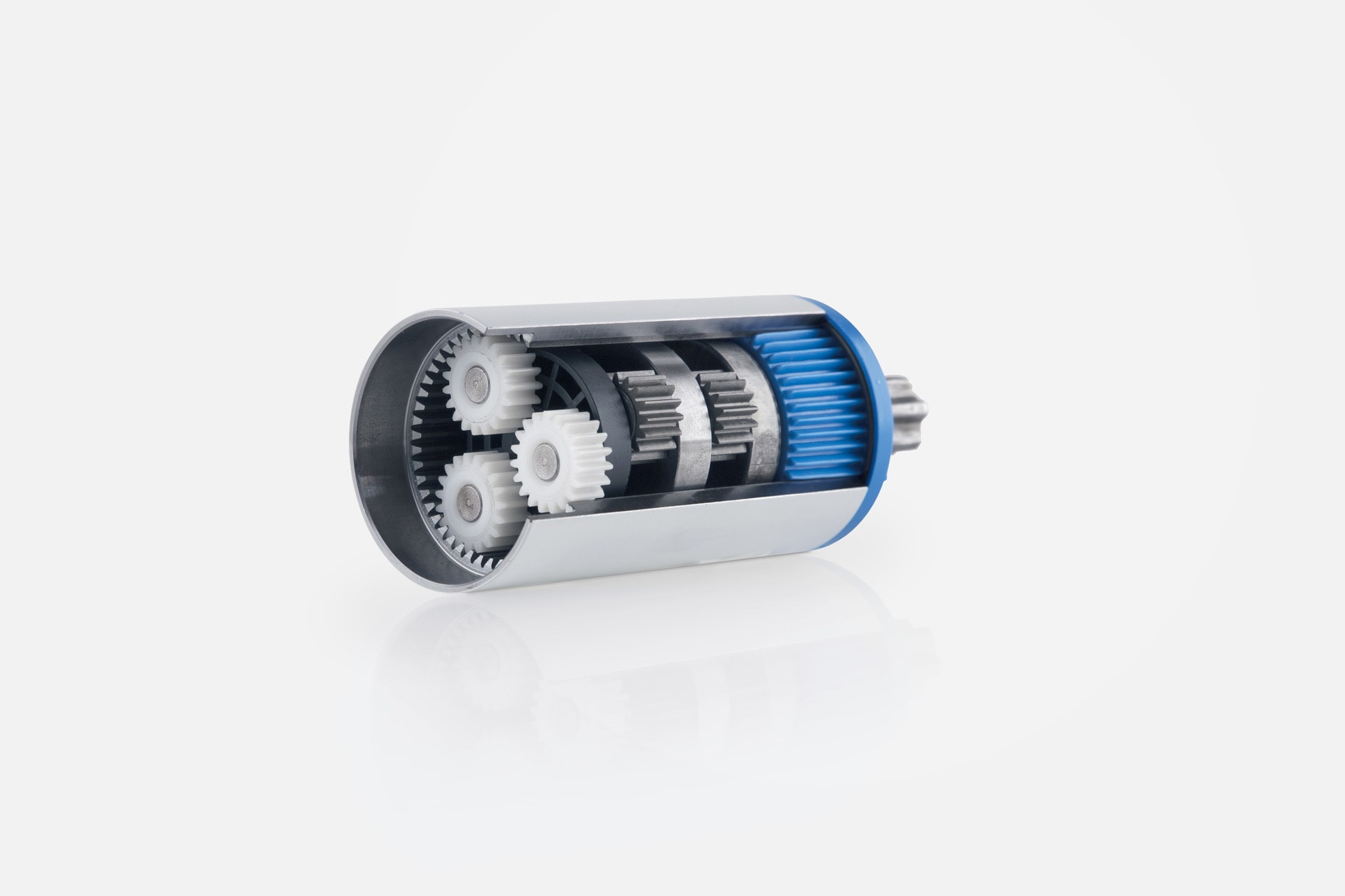

Planetary gearsPlanetary gears

Planetary gearsPlanetary gears -

Spur gearsSpur gears

Spur gearsSpur gears -

Other gear typesOther gear types

Other gear typesOther gear types -

Can’t find the product you’re looking for?

No problem – customised solutions are our standard.

-

Your contact

Harald Ketterer

Sales Gears & Geared Motors

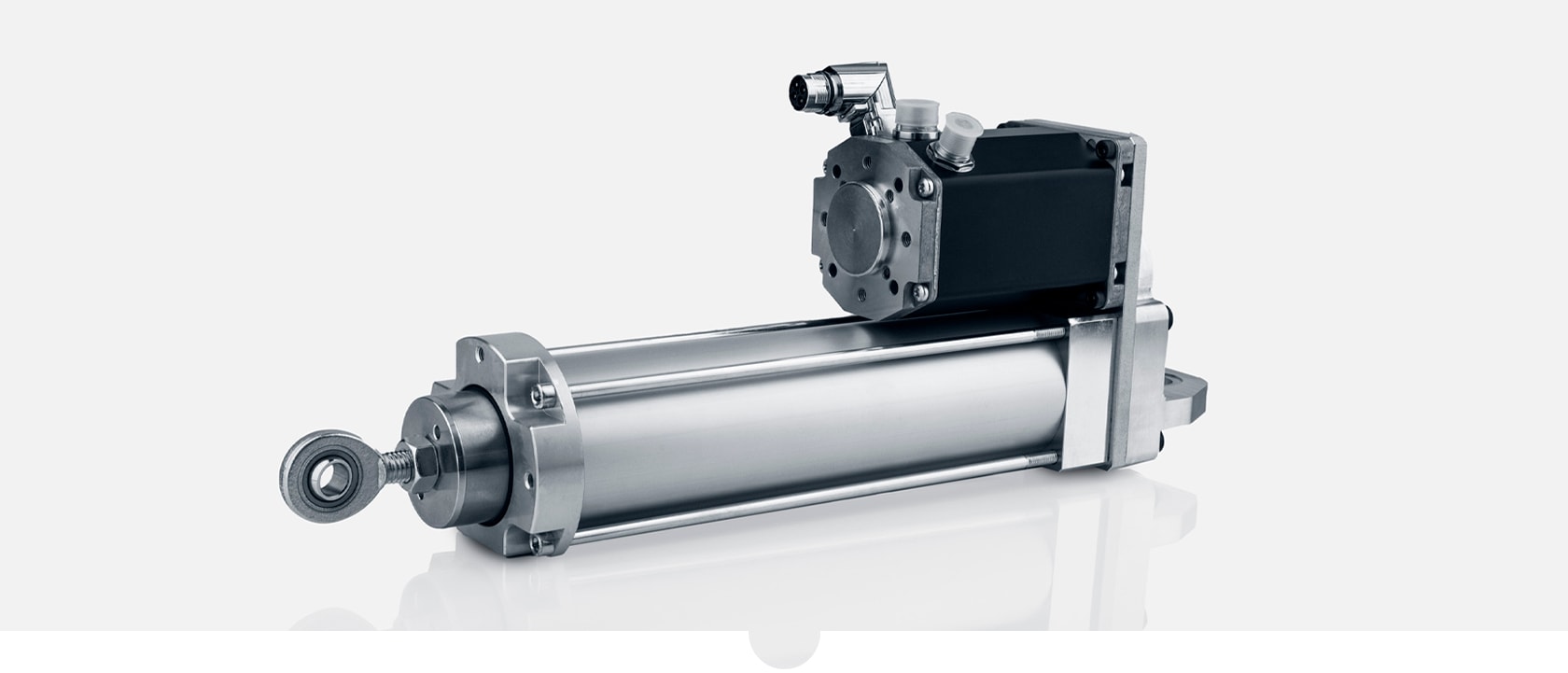

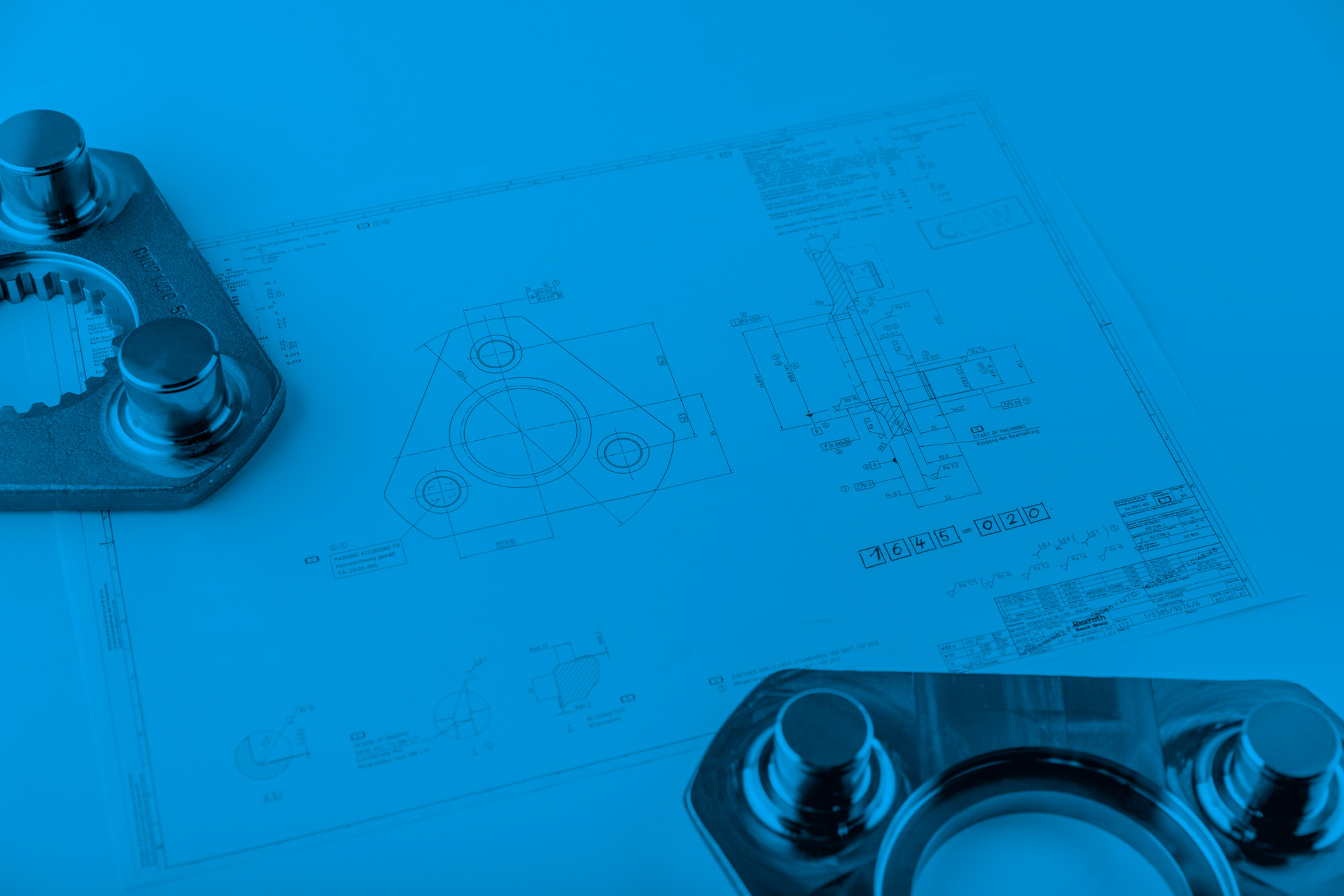

Customised Drives

Individual challenges call for individual solutions

Complex requirements, such as confined spaces or challenging performance data, mean that in many applications standard gears are unsuitable. As a leading manufacturer of special-purpose gearing solutions, we develop bespoke drives tailored to your individual application but based on our broad product portfolio. Our drive solutions enjoy an excellent reputation for quality, reliability and loadability. Our products are chosen whenever the demands are particularly extreme – impeccably smooth running in medical technology, robustness and durability in conveyor systems or exceptional reliability in food processing.

We’d be delighted to develop the perfect gear solution to meet your requirements.

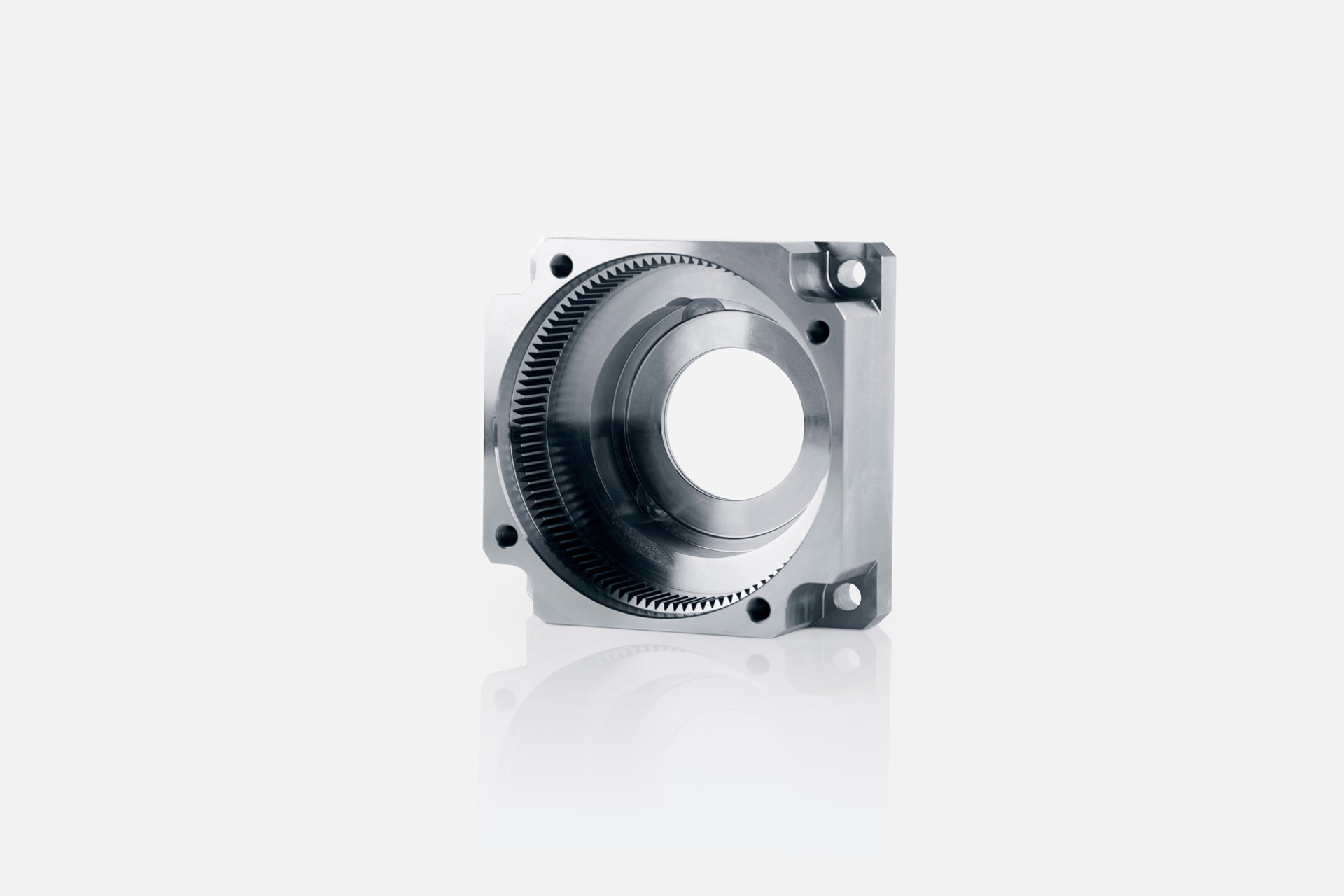

Gear Parts

-

Spur wheelsSpur wheels

Spur wheelsSpur wheels -

Pinions & motor shaftsPinions & motor shafts

Pinions & motor shaftsPinions & motor shafts -

Ring gearsRing gears

Ring gearsRing gears -

Planetary carriersPlanetary carriers

Planetary carriersPlanetary carriers -

Gear housingsGear housings

Gear housingsGear housings -

Other gear partsOther gear parts

Other gear partsOther gear parts -

Can’t find the product you’re looking for?

No problem – customised solutions are our standard.

-

Your contact

Stefanie Fricke

Sales Gear Parts

-

Your contact

Stefan Hörmann

Sales Gear Parts

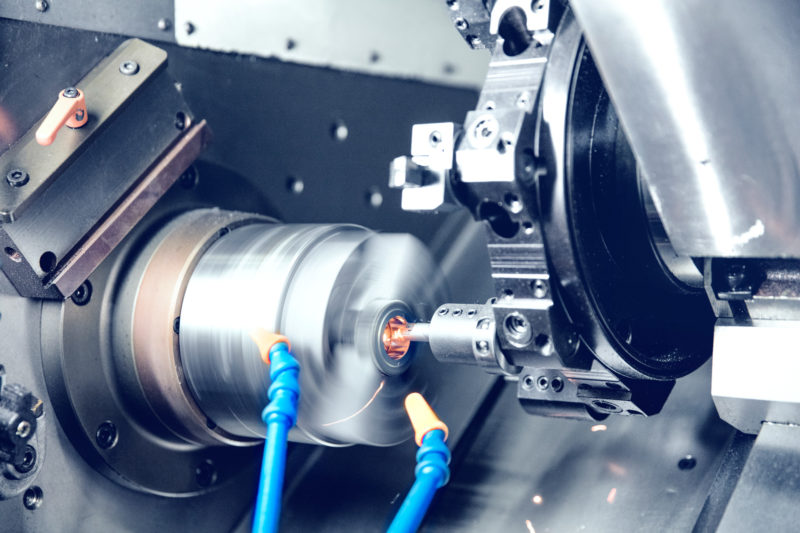

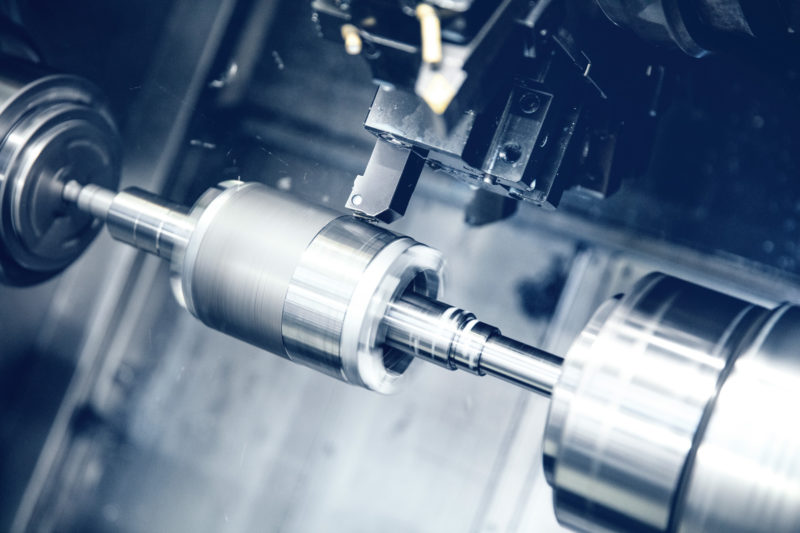

Technologies

The right technology for every requirementOur technically and economically optimised products are manufactured using the following technologies:

• Gear hobbing

• Gear shaping

• Gear broaching

• Tooth flank grinding

• Skive hobbing

• Gear honing

• Cylindrical grinding

• Hard turning

• CNC turning

• CNC milling

• Assembly

• Refining

• Labeling

Applications

GSC Schwörer products are used successfully in many different applications around the world. We scrutinise your industry closely, assess the conditions and constraints, and then develop a drive solution which is fine-tuned to your individual needs.

-

Materials handling

Materials handling -

Professional tools

Professional tools -

Medical technology

Medical technology -

Building services

Building services -

Electromobility

Electromobility -

Process technology

Process technology